Best Hydroponic Pumps Review: The Basic Guide To Water Systems

Key Takeaways

- Selecting the right pump size is critical – an undersized pump can starve your plants of nutrients while an oversized one wastes energy and creates excessive turbulence

- Water pumps circulate nutrient solution while air pumps oxygenate your reservoir – most systems need at least one, and sometimes both

- The Active Aqua AAPW250 stands out as the best overall water pump for hydroponics, offering excellent reliability and value

- Head height significantly affects pump performance – a pump rated for 400 GPH might only deliver 250 GPH when pushing water upward

- Happy Hydro Farm offers comprehensive hydroponic system solutions that perfectly complement these pumps for optimal growing results

Why Your Hydroponic Pump Makes or Breaks Your System

“LetPot Replacement Cycling Pump (se/mini)” from letpot.com and used with no modifications.

Your hydroponic pump is the beating heart of your entire growing operation. Without proper water circulation and oxygenation, your carefully calculated nutrient solution becomes stagnant, leading to root disease and eventual crop failure. The pump you choose determines whether nutrients reach every plant evenly, whether your system maintains proper oxygen levels, and ultimately, whether your plants thrive or merely survive.

I’ve seen countless hydroponic setups fail simply because the grower tried to save a few dollars on an inadequate pump. Selecting the right pump isn’t just about flow rate—it’s about reliability, efficiency, and matching the exact needs of your specific system type. Happy Hydro Farm specializes in hydroponic equipment that ensures your plants receive optimal conditions for growth without the guesswork that often plagues beginners.

Think of your hydroponic pump like the heart in a circulatory system—it needs to be powerful enough to push nutrient solution to the furthest reaches of your setup while gentle enough not to damage delicate root systems. The wrong choice means uneven growth, nutrient deficiencies in some plants, and potential system failures that can wipe out weeks of careful cultivation overnight.

Types of Hydroponic Pumps You Need to Know

“Hydroponics Air Pump, One-Outlet …” from acinfinity.com and used with no modifications.

Navigating the world of hydroponic pumps can be overwhelming at first glance. The market offers dozens of options, but they generally fall into two main categories: water pumps and air pumps. Understanding the fundamental differences between these types and when to use each one is critical to building a successful hydroponic garden.

Water Pumps vs. Air Pumps: What’s the Difference?

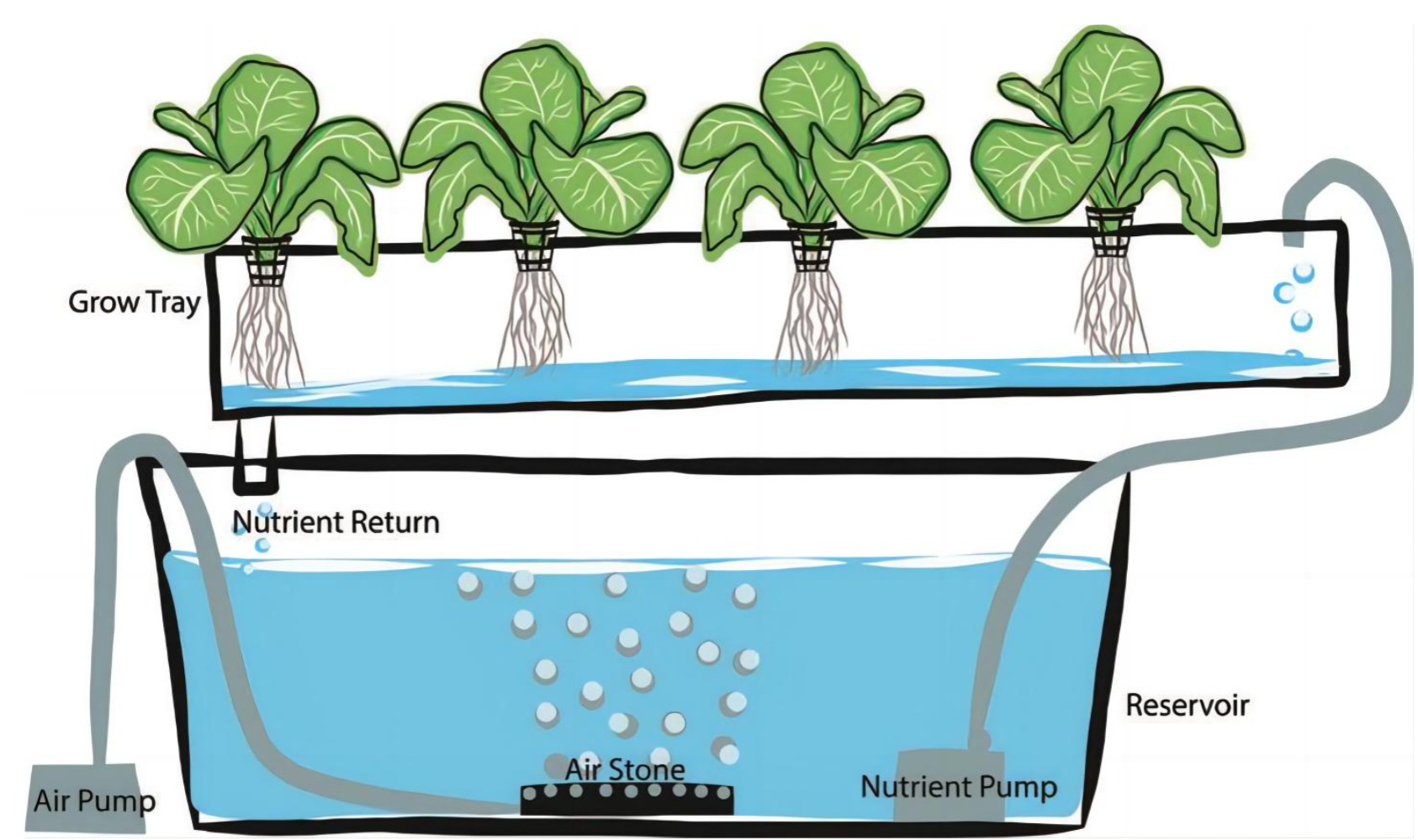

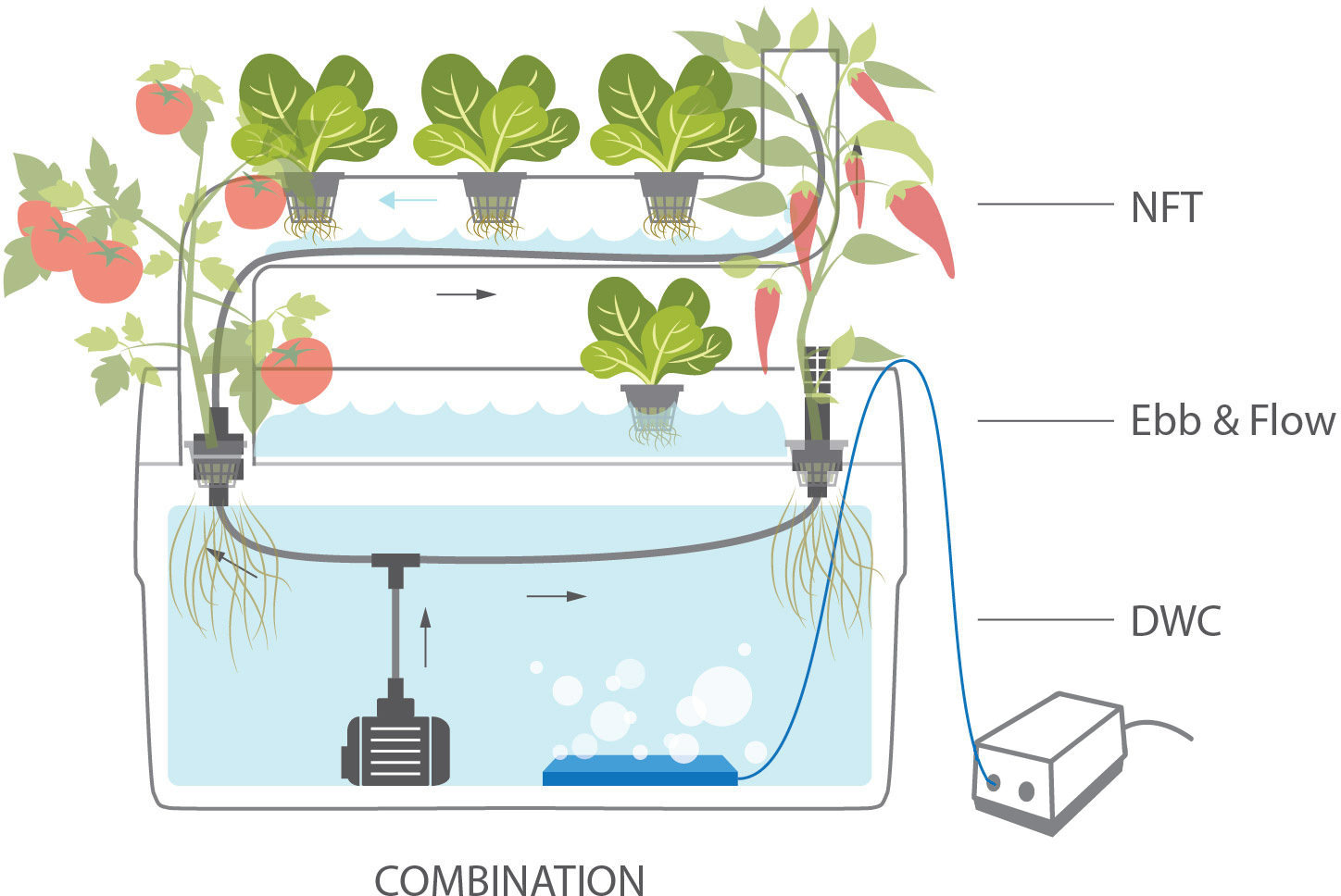

Water pumps and air pumps serve completely different functions in a hydroponic system, and many setups require both. Water pumps move your nutrient solution throughout the system, delivering essential nutrients to plant roots. They’re critical in systems like nutrient film technique (NFT), ebb and flow, and drip systems where water needs to be actively moved from a reservoir to your growing containers. Air pumps, on the other hand, don’t move water at all—they push air through air stones to create bubbles in your nutrient reservoir, increasing dissolved oxygen content. These are absolutely essential for deep water culture (DWC) systems where roots are constantly submerged. Without adequate oxygenation, root rot quickly sets in, destroying your crop. Many growers use both types in hybrid systems to maximize both nutrient delivery and oxygenation.

Submersible vs. External Water Pumps

Water pumps come in two primary configurations: submersible and external. Submersible pumps are designed to operate completely underwater inside your nutrient reservoir. They’re typically more affordable, easier to install, and offer the advantage of being naturally cooled by the surrounding water. I recommend submersible pumps for most home growers due to their simplicity and reasonable noise levels.

External pumps mount outside the reservoir and draw water through an intake hose. These pumps tend to be more powerful and efficient for larger systems, but they require more complex plumbing, can be louder, and generate more heat. Commercial operations often prefer external pumps because they’re easier to access for maintenance and can handle higher flow rates necessary for extensive growing operations. The tradeoff is higher initial cost and more complex installation requirements.

DC vs. AC Pumps: Power Options Explained

The power source for your pump is another critical consideration that affects performance, efficiency, and operating costs. AC pumps plug directly into standard wall outlets and generally offer higher flow rates at lower purchase prices. They’re the most common choice for indoor growers with ready access to electrical outlets. The downside is they consume more electricity over time and cannot operate during power outages without backup systems.

DC pumps run on direct current, typically from batteries or solar panels. These pumps are significantly more energy-efficient, consuming 60-80% less power than comparable AC models. For off-grid operations or those concerned about electricity costs, DC pumps offer substantial long-term savings despite higher initial investment. Some advanced DC pumps even offer variable speed controls, allowing you to adjust flow rates based on your plants’ changing needs throughout their growth cycles. To understand more about the energy efficiency of hydroponic systems, check out our guide on hydroponics explained.

How to Calculate the Perfect Pump Size for Your System

“Hydroponics Air Pump, Two-Outlet …” from acinfinity.com and used with no modifications.

Selecting the right pump size is perhaps the most critical decision you’ll make when setting up your hydroponic system. Too small, and your plants will suffer from inadequate nutrient flow and oxygen; too large, and you’ll waste electricity while potentially damaging delicate root systems with excessive water pressure. Getting this calculation right the first time saves headaches down the road.

Understanding GPH (Gallons Per Hour) Requirements

GPH (Gallons Per Hour) is the standard measurement of a pump’s flow capacity. As a general rule, your water pump should be able to circulate the entire volume of your nutrient reservoir at least once per hour. For example, if your reservoir holds 20 gallons, you need a minimum pump rating of 20 GPH. However, this is the absolute minimum, and most successful systems actually cycle their entire water volume multiple times per hour for optimal results.

For most home systems, I recommend a pump that can cycle your reservoir 2-3 times per hour. This ensures thorough mixing of nutrients and prevents stagnation without creating excessive turbulence. For systems with multiple growing channels or plants with high water demands (like fruiting vegetables), aim for 3-4 reservoir turnovers per hour to maintain peak nutrient availability and oxygen levels throughout your system.

Measuring Head Height and Why It Matters

Head height is the vertical distance from your pump to the highest point where water needs to be delivered. This measurement is absolutely crucial because pump performance decreases significantly with height. A pump rated for 400 GPH at zero head height might only deliver 250 GPH when pushing water 3 feet upward, and could drop to under 100 GPH at 6 feet.

To properly account for head height, measure from the surface of your reservoir water to the highest point in your system where water needs to flow. Then check the manufacturer’s head height chart for your potential pump. Always choose a pump with enough power to deliver your required flow rate at your specific head height, not just at zero elevation. Vertical systems particularly demand careful attention to head height calculations since they can easily exceed 5-6 feet in height. For more insights, explore our guide on best vegetables for hydroponics.

System-Specific Flow Rate Requirements

System Type Minimum Flow Rate Optimal Flow Rate Special Considerations NFT (Nutrient Film Technique) 1-2 GPH per channel 2-3 GPH per channel Thin film only, avoid flooding channels Ebb and Flow Reservoir volume per hour 2x reservoir volume per hour Must fill tray within 5-10 minutes Dutch Bucket/Bato 2 GPH per bucket 4 GPH per bucket Account for drain time in calculations Vertical Tower 2 GPH per tower 3-4 GPH per tower Head height significantly reduces flow DWC (Deep Water Culture) 0.5-1 liter per minute of air 1-2 liters per minute of air Requires air pump, not water pump

The One-Hour Reservoir Turnover Rule

The one-hour reservoir turnover rule is a reliable baseline that serves most hydroponic systems well. This principle states that your pump should be capable of moving the entire volume of your nutrient solution through your system at least once per hour. For example, if your total system contains 50 gallons of nutrient solution, your pump should have a minimum rating of 50 GPH after accounting for head height losses.

For more demanding crops like tomatoes or peppers, I often recommend increasing this to a 30-minute turnover (twice the minimum GPH) to ensure abundant nutrient delivery during peak fruiting periods. Remember that these calculations represent minimum requirements – it’s always better to have slightly more pumping capacity than you need rather than not enough. A pump that’s too powerful can always be regulated with a valve, but an underpowered pump can’t be made more powerful.

Top 5 Water Pumps for Hydroponic Systems

“Hydroponic Culture Pump Solution” from www.streampumps.com and used with no modifications.

After testing dozens of pumps across various system types and growing conditions, I’ve identified the five standout performers that consistently deliver reliable results for hydroponic growers. These selections balance performance, durability, energy efficiency, and value to meet the needs of different system sizes and budgets.

1. Active Aqua AAPW250: Best Overall Water Pump

The Active Aqua AAPW250 delivers exceptional performance with its 250 GPH flow rate that can handle systems with up to 100 gallons of nutrient solution. What sets this pump apart is its remarkable balance of power, reliability, and energy efficiency—consuming only 8 watts while operating whisper-quiet at under 35 decibels. I’ve run multiple units continuously for over two years without a single failure, making it my top recommendation for serious hydroponic enthusiasts. The ceramic shaft and impeller design significantly reduce wear compared to competitors, while the adjustable flow control lets you dial in precisely the right flow for your system’s needs without wasting energy.

2. VicTsing 80 GPH Submersible: Best for Small Systems

For small hydroponic setups with reservoirs under 20 gallons, the VicTsing 80 GPH submersible pump offers perfect performance at an entry-level price point. This compact powerhouse measures just 2.6 x 1.5 x 2 inches but delivers consistent water flow ideal for single DWC buckets, small NFT channels, or starter systems. What I particularly appreciate about this pump is its ultra-low 2.5-watt power consumption and the included three nozzle attachments that allow easy adaptation to different tubing sizes without purchasing additional fittings. While it lacks the longevity of premium models, its performance-to-price ratio makes it the obvious choice for beginners or those running multiple small independent systems. For those new to hydroponics, understanding hydroponics explained can be incredibly beneficial.

3. EcoPlus 396 GPH: Best Mid-Range Pump

The EcoPlus 396 GPH pump hits the sweet spot for medium-sized hydroponic systems serving 4-6 plants or multiple growing channels. With a maximum lift height of 6.6 feet, it can easily service vertical systems while maintaining excellent flow rates. The oil-free, magnetically driven design runs cooler than comparable models, extending its operational lifespan while reducing the risk of overheating when running continuously.

What impresses me most about the EcoPlus is its exceptional energy efficiency—drawing just 20 watts while delivering nearly 400 gallons per hour. This means significant electricity savings over time compared to less efficient competitors. The pump includes 1/2″ and 3/4″ fittings to accommodate various tubing sizes, eliminating compatibility headaches during installation.

I’ve found the EcoPlus particularly well-suited for ebb and flow systems where its strong initial flow quickly fills growing trays, while its adjustable flow control allows perfect fine-tuning of the flood cycle. The ceramic shaft and impeller design significantly reduces wear compared to plastic components, providing reliable operation for years rather than months. If you’re interested in learning more about sizing hydroponic water pumps, check out this guide on sizing hydroponic water pumps.

4. Hydrofarm Active Aqua AAPW1000: Best for Large Systems

For commercial growers or large home systems, the Hydrofarm Active Aqua AAPW1000 delivers industrial-grade performance that justifies its higher price tag. This workhorse pushes 1000 GPH at zero head height and maintains an impressive 750 GPH even at a 4-foot elevation. What truly sets this pump apart is its exceptional durability under continuous heavy load—I’ve seen these units run for 3+ years in commercial operations without failure.

The AAPW1000 features a robust dual-impeller design that creates consistent pressure even when pushing water through complex distribution systems with multiple growing channels. Its large intake screen prevents clogging while still being easy to access for cleaning, a crucial feature for long-term maintenance.

- Maintains 600+ GPH flow rate at 6 feet head height

- Includes 1/2″, 3/4″, and 1″ outlet adapters for versatile installation

- Ceramic shaft and bearing construction minimizes wear

Despite its power, this pump operates at a reasonable noise level (around 45dB) and consumes only 92 watts—significantly less than comparable commercial pumps. The built-in thermal protection automatically shuts the pump down if it overheats, preventing damage and potential system failures. For more insights on maintaining your hydroponic system, check out this guide on maintaining water quality in hydroponics.

For growers running NFT systems with 8+ channels, multiple ebb and flow tables, or large DWC systems, this pump provides the perfect balance of power, reliability, and efficiency. The 6.5-foot heavy-duty power cord adds installation flexibility while the optional flow controller allows precise adjustment to match your system’s specific requirements.

5. Vivosun 800 GPH: Best Budget-Friendly Option

The Vivosun 800 GPH pump delivers surprising performance at a price point that won’t break your budget. While it lacks some of the premium features of higher-end models, it provides reliable operation for medium to large hydroponic systems. This workhorse can handle multiple growing channels or a large ebb and flow table with ease, making it perfect for growers who need significant flow without premium pricing.

I’ve found the Vivosun particularly impressive for its 12-foot power cord—significantly longer than competitors—which adds tremendous installation flexibility to awkward grow spaces. The pump includes three different outlet adapters (1/2″, 3/4″, and 1″) and two flow adjusters, eliminating the need for additional purchases. Despite its budget classification, the pump’s epoxy-protected motor housing has proven surprisingly durable in long-term testing, handling continuous operation better than other pumps in this price range.

One minor drawback is the slightly higher noise level (approximately 45-48dB) compared to premium options, but this is rarely noticeable when the pump is submerged in a covered reservoir. For growers balancing performance needs with budget constraints, the Vivosun 800 GPH represents exceptional value that doesn’t compromise on essential features.

Top 3 Air Pumps for Deep Water Culture Systems

“Air Pumps for Supragarden® – The …” from www.supragarden.com and used with no modifications.

Deep Water Culture (DWC) systems rely entirely on air pumps to deliver oxygen to submerged roots. Without adequate oxygenation, root rot quickly sets in, destroying your crop. These top three air pumps consistently outperform competitors in reliability, output, and energy efficiency.

1. Hygger Quiet Mini Air Pump: Best for Small DWC Systems

The Hygger Quiet Mini Air Pump delivers exceptional performance for small DWC systems with 1-4 buckets. What sets this pump apart is its remarkably quiet operation at just 33dB—practically whisper-quiet compared to most air pumps that sound like small jackhammers. Despite its compact size, it pushes a consistent 1.5L/min of air through dual outlets, providing ample oxygenation for young plants or small-scale systems.

The Hygger’s piezoelectric technology completely eliminates the vibration issues common with diaphragm-based competitors, making it ideal for indoor grows where noise matters. An added bonus is its energy efficiency—consuming only 1.8 watts while operating continuously. For beginners or those with limited space, this pump provides perfect performance without the industrial noise that plagues many hydroponic setups.

2. Hydrofarm Active Aqua AAPA7.8L: Best for Commercial Setups

For serious growers with multiple DWC buckets or commercial operations, the Hydrofarm Active Aqua AAPA7.8L delivers professional-grade performance. This powerhouse pushes an impressive 7.8 liters per minute through four outlets, easily supporting 8-12 large DWC buckets or multiple growing containers. The reinforced rubber diaphragm and electromagnetic air compressor are specifically engineered for 24/7 operation, resulting in exceptional reliability even under constant use. If you’re interested in exploring the world of hydroponics further, check out our guide on hydroponics explained for more insights.

What truly distinguishes this pump is its pressure consistency—it maintains stable output even when connected to multiple air stones or diffusers with varying resistance levels. The adjustable manifold lets you control flow to each outlet independently, allowing customization for different plant types or growth stages within the same system. While not the quietest option (around 45dB), its output-to-noise ratio is significantly better than most high-volume pumps, and the included hanging kit helps further reduce vibration noise.

I’ve tested this pump extensively in large systems where it ran continuously for over 18 months without requiring maintenance or showing decreased output—an exceptional track record in this product category. The 8-foot power cord adds installation flexibility while the weather-resistant housing provides protection in humid grow environments. For more information on choosing the right pump, check out this guide on sizing hydroponic water pumps.

3. Tetra Whisper: Most Reliable Budget Air Pump

The Tetra Whisper proves that reliable aeration doesn’t require a significant investment. This pump has been a staple in the aquarium industry for decades, and its dome-shaped design and quality components make it perfectly suited for small to medium hydroponic applications. Available in multiple sizes, the 100-gallon model pushes enough air for 4-6 DWC buckets while remaining one of the most affordable options on the market. For those interested in related hydroponic systems, exploring maintaining water quality in fishtank hydroponics can be beneficial.

What impresses me about the Tetra Whisper is its exceptional longevity despite its modest price point. The rubber feet effectively minimize vibration transfer, resulting in quieter operation than many pricier competitors. While it lacks the multiple outlets of premium models, its consistent output and reliability more than compensate for this limitation in smaller systems. For beginners or budget-conscious growers, this pump offers the perfect balance of performance and value without compromising on the essential function of keeping roots properly oxygenated.

Installation Tips to Maximize Pump Performance

Proper installation can dramatically extend your pump’s lifespan while ensuring optimal performance. These practical techniques address the most common installation mistakes I’ve encountered when consulting with hydroponic growers.

Proper Positioning and Mounting

Correct pump positioning starts with ensuring your water pump sits flat on the reservoir bottom or is suspended slightly above it to prevent intake clogging. Never operate a submersible pump without being fully submerged, as this causes overheating and premature failure. For external pumps, mount them below the water level when possible to improve priming and reduce strain.

Air pumps should always be positioned above the water level to prevent back-siphoning if power fails. Use check valves on air lines as an additional safeguard. Mounting air pumps on foam pads or rubber feet significantly reduces vibration noise transfer to surrounding surfaces. For larger systems, consider wall-mounting pumps using rubber isolation mounts to minimize both noise and counter space usage.

Tubing Selection and Maintenance

Tubing diameter dramatically impacts pump performance—undersized tubing creates back pressure that reduces flow rates and forces pumps to work harder. As a rule, water pump tubing should match or exceed the pump’s outlet size. For runs longer than 10 feet, consider increasing the diameter by 1/4 inch to reduce friction losses. Black tubing prevents algae growth that can clog systems, while thick-walled variants resist kinking that restricts flow.

Implement quarterly maintenance by flushing all tubing with a 3% hydrogen peroxide solution to clear biofilm buildup that gradually restricts flow. Install T-fittings with caps at system low points to make this cleaning process easier. For air lines, avoid excessive tubing length and minimize bends—each 90° turn reduces airflow by approximately 10%. Regular inspection for pinched tubing can prevent many common flow problems before they affect plant health.

Preventing Overheating and Extending Pump Life

Overheating is the primary killer of hydroponic pumps, but several simple strategies can dramatically extend operational lifespan. For submersible pumps, always maintain proper water levels in reservoirs—even partial exposure can cause rapid temperature increases. Clean intake screens weekly to prevent clogging that restricts cooling water flow through the motor housing. Consider adding an aquarium thermometer to your reservoir as an early warning system—water temperature increases often indicate pump issues before complete failure occurs.

For air pumps, adequate ventilation is critical. Allow at least 4 inches of clearance around air intakes and avoid enclosed cabinets that trap heat. In hot environments, a small computer fan directed at the pump can provide supplemental cooling that dramatically extends service life. Finally, install inexpensive outlet timers to cycle pumps periodically in systems where continuous operation isn’t critical—even 15 minutes off per 4 hours can significantly reduce wear and heat buildup without compromising plant health.

Common Pump Problems and How to Fix Them Fast

“Water Pump Setup For Hydroponic System …” from www.youtube.com and used with no modifications.

Even the best pumps eventually develop issues, but most common problems have simple solutions that don’t require replacement. These troubleshooting techniques address the most frequent complaints I hear from hydroponic growers.

Troubleshooting Low Flow Issues

When pump output suddenly decreases, start by checking the intake screen for debris or root matter that restricts water entry. Cleaning this screen alone resolves approximately 70% of flow problems in established systems. If the intake is clear, examine all tubing for kinks or compression points that might restrict flow, particularly where tubes pass through grommets or tight spaces. For more insights on maintaining your hydroponic system, consider sizing hydroponic water pumps effectively.

For persistent flow issues, disconnect the pump and inspect the impeller assembly for mineral buildup or algae growth. Soaking in a 50% white vinegar solution for 30 minutes dissolves most mineral deposits without damaging components. After cleaning, test the pump in a bucket of clean water to verify restored flow before reinstallation. If flow remains inadequate, check your head height calculations—as systems grow, additional components often increase resistance beyond the pump’s original specifications, necessitating an upgrade.

Dealing with Loud Pump Noise

Excessive noise often indicates a pump that’s running dry or has air trapped in the impeller housing. For submersible pumps, ensure they’re completely submerged and gently tilt them while running to release trapped air bubbles. Unexpected vibration noise frequently stems from pumps contacting reservoir walls—repositioning or adding rubber padding often provides immediate improvement. For more information on selecting the right pump, check out this guide on sizing hydroponic water pumps.

For air pumps, place them on foam pads to absorb vibrations, and check that hanging models aren’t contacting walls or other surfaces. Replace worn diaphragms in air pumps when buzzing noises develop, as this indicates the end of their effective service life. Consider housing particularly noisy pumps inside simple foam-lined boxes—even basic sound insulation can reduce perceived noise by 40-60% without affecting performance.

Fixing Leaks and Connection Problems

Leaks typically occur at connection points rather than in pumps themselves. Inspect all barbed fittings and replace any showing signs of cracking or brittleness. For persistent leaks, avoid overtightening threaded connections—instead, use PTFE (plumber’s) tape on threads or food-grade silicone sealant for barbed connections. When using clamps on tubing, position them approximately 1/8 inch from the end of the barb for optimal sealing without damaging the fitting.

For leaks around pump housings, check for cracked components that may have resulted from freezing or impact damage. While minor housing cracks can sometimes be repaired with waterproof epoxy, this is generally a temporary solution—start budgeting for replacement while implementing the repair. Finally, ensure that tubing has straight, clean cuts at connection points, as angled or jagged cuts rarely form proper seals regardless of clamp pressure.

The Final Verdict: Choosing the Right Pump for Your Hydroponic Journey

After extensive testing across multiple system types and growing scenarios, the Active Aqua AAPW250 stands out as the best overall water pump for most hydroponic growers. Its exceptional reliability, efficiency, and five-year average lifespan deliver outstanding value despite its slightly higher initial cost. For systems with higher demands, the Hydrofarm Active Aqua AAPW1000 provides unmatched performance for larger operations.

For DWC systems requiring air pumps, the Hydrofarm Active Aqua AAPA7.8L delivers the perfect balance of output, reliability, and reasonable noise levels. Budget-conscious growers should strongly consider the Tetra Whisper, which provides surprising longevity and performance at an entry-level price point.

“The right pump isn’t always the most powerful or the most expensive—it’s the one that perfectly matches your system’s specific requirements while providing reliable operation. Calculate your needs carefully, then choose accordingly.”

Remember that proper sizing remains the most critical factor in pump selection. An undersized pump will struggle continuously, failing prematurely and potentially damaging plants through inadequate nutrient delivery. Conversely, an oversized pump wastes electricity and may create excessive turbulence that stresses delicate root systems. Take the time to calculate your specific requirements using the guidelines provided earlier, factoring in both current needs and reasonable room for system expansion.

Regardless of which pump you select, implementing the installation and maintenance practices outlined in this guide will significantly extend its operational life. Regular cleaning, proper positioning, and occasional preventive maintenance represent minimal investments that yield substantial returns through improved reliability and performance. For more details on choosing the right pump, check out this guide on sizing hydroponic water pumps.

Frequently Asked Questions

These answers address the most common questions I receive from hydroponic growers about pump selection and maintenance.

How often should I replace my hydroponic pump?

Quality water pumps typically last 2-5 years with proper maintenance, while air pumps generally need replacement every 1-3 years depending on usage patterns and environmental conditions. Rather than following a fixed schedule, monitor performance indicators like decreased flow rates, increased noise, or unusual vibration—these signal that replacement may be necessary soon. Preventive replacement of critical pumps in commercial operations is often warranted at the 75% mark of expected lifespan to avoid crop losses from unexpected failures. For more information on maintaining your hydroponic system, check out this guide on hydroponics explained.

Can I use a fish tank pump for my hydroponic system?

Aquarium pumps can work for small hydroponic systems but are generally not ideal for sustained operation. While submersible aquarium water pumps may suffice for very small systems (under 5 gallons), they typically lack the flow rates and durability needed for most hydroponic applications. Aquarium air pumps can work reasonably well for small DWC systems but often lack the output consistency and reliability of dedicated hydroponic models. If budget constraints necessitate using aquarium pumps, select models rated for significantly larger tanks than your actual system size to ensure adequate performance. For more information on hydroponic systems, you can explore hydroponics explained.

Why is my water pump making unusual noises?

Unusual pump noises typically indicate either mechanical issues or installation problems. Grinding or scraping sounds usually point to impeller damage from debris or mineral buildup, requiring disassembly and cleaning or part replacement. High-pitched whining often indicates bearings that are running dry or wearing out—a sign that replacement may be necessary soon.

Rattling or vibration noises frequently stem from improper mounting rather than pump defects. Ensure the pump isn’t contacting hard surfaces directly by using rubber feet or suspending submersible models slightly above the reservoir bottom. For external pumps, check that inlet and outlet plumbing isn’t transferring vibration to surrounding structures and that mounting bolts haven’t loosened over time.

Do I need both an air pump and a water pump?

System design determines pump requirements. Deep Water Culture (DWC) systems primarily need air pumps to oxygenate water where roots remain constantly submerged. Nutrient Film Technique (NFT), ebb and flow, and drip systems require water pumps to circulate nutrient solution. Hybrid systems like those combining DWC with periodic flooding often benefit from both pump types. For small systems where simplicity is paramount, a single high-quality water pump with venturi fittings or waterfall returns can provide adequate oxygenation without a separate air pump, though dedicated air pumps deliver superior oxygenation in most scenarios.

What’s the best way to clean my hydroponic pump?

For submersible water pumps, monthly cleaning prevents most common issues. Disconnect power, remove the pump, and disassemble according to manufacturer instructions—typically by removing the intake screen and impeller housing. Soak all components in a 50/50 solution of white vinegar and water for 30 minutes to dissolve mineral deposits, then scrub gently with a soft brush. Inspect the impeller for damage and ensure it rotates freely before reassembly. For air pumps, replace filters quarterly and clean external surfaces with a damp cloth to prevent dust accumulation that restricts airflow and causes overheating. Regular maintenance is crucial for maintaining water quality in your hydroponic systems.

Always maintain a clean reservoir environment to minimize pump cleaning frequency. Using root zone barriers like net pots or mesh screens prevents root material from reaching pump intakes, while regular reservoir cleaning reduces algae and biofilm buildup that gradually degrades pump performance. For more information on maintaining optimal pump efficiency, consider sizing hydroponic water pumps. Remember that preventive maintenance takes minutes but can extend pump life by years.

Remember that the heart of any hydroponic system lies in its circulation. Investing in quality pumps and maintaining them properly pays dividends through healthier plants, higher yields, and fewer system failures. By following the guidelines in this review, you’ll be well-equipped to select the perfect pumps for your unique growing environment.

- Regularly inspect all pumps and connections monthly

- Keep spare parts for critical system components

- Document pump performance to identify gradual degradation

- Consider redundant pumps for valuable crops or large systems

For growers seeking complete peace of mind, consider automated monitoring systems that alert you to pump failures or performance issues before they affect plant health. These systems represent a small investment compared to the potential loss of an entire crop from circulation failures.